Recycling Earth, Computing the Cosmos

The market has been restless lately as earnings season unfolds, but instead of getting lost in the short-term noise, we’re turning our focus to something bigger. In this issue, we’re exploring the kinds of long-horizon ideas and bold engineering efforts that carry lasting value—the projects that have the potential to reshape industries and, in some cases, humanity’s future.

1. PsiQuantum: Building the Future with Light

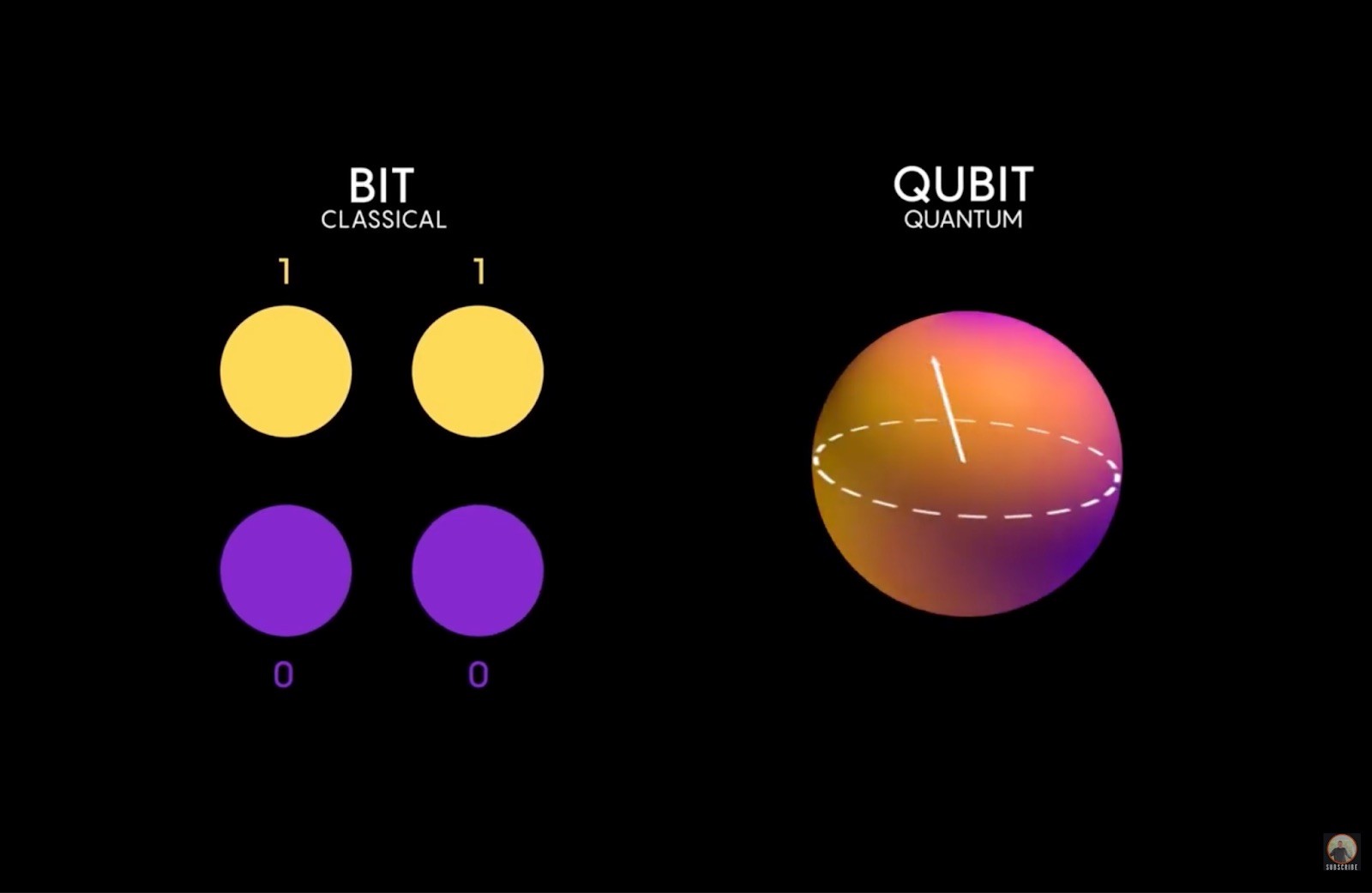

In an inconspicuous corner of Palo Alto, a team of physicists is chasing one of the most audacious dreams in technology: building the world’s first fault-tolerant quantum computer. Their company, PsiQuantum, isn’t betting on superconducting loops or trapped ions like many of its rivals. Instead, it’s building with light - using photons as qubits - and manufacturing its chips in the same kind of foundries that produce everyday silicon processors.

PsiQuantum was founded in 2016 by four quantum-optics pioneers: Jeremy O’Brien (CEO), Terry Rudolph (chief architect), Pete Shadbolt (CSO), and Mark Thompson (chief technologist). All were leading figures in photonic quantum research before deciding that scaling up their work would require something beyond what academia could offer. Their big idea: take quantum hardware out of the lab and into the factory.

PsiQuantum’s mission is to build the first commercially useful, fault-tolerant, million-qubit quantum computer using photonic qubits manufactured in high-volume semiconductor fabs. Its chips are fabricated on wafer-scale silicon photonics platforms, through partnerships such as GlobalFoundries. The company’s new “Omega” chipset integrates high-performance photonic components at scale, repurposing mature photonics technology from telecom and datacenter networks to encode and route qubits. A recent Nature paper details PsiQuantum’s manufacturable platform for photonic quantum computing, an approach that could prove more scalable than other architectures if large-scale foundry integration succeeds.

Difference between Light (Psiquantum) and Superconductors (Google’s Willow)

Where Google’s Willow chip uses superconducting transmon qubits operating at cryogenic temperatures, PsiQuantum’s qubits are photons: particles of light guided through tiny silicon waveguides.

Google’s Willow is the most advanced demonstrated system today, showing exponential error reduction and record-breaking benchmarks on a 100-plus-qubit chip.

PsiQuantum’s photonic platform, by contrast, aims for manufacturability and room-temperature operation. It trades short-term demonstrations for long-term scalability: millions of qubits fabricated in semiconductor fabs rather than cryogenic labs.

Superconducting systems lead in current performance; photonic systems promise a higher ceiling once the technology matures. In short, Willow proves what’s possible now, PsiQuantum is building what might be necessary later.

Backed by BlackRock, Nvidia’s NVentures, and government partners in Australia and the U.S., PsiQuantum has raised more than US $2 billion, including a US $1 billion Series E in 2025. Its Brisbane facility, supported by an A$1 billion public package, is expected to host one of the world’s first large-scale quantum computers.

The road ahead is steep though: integrating millions of optical components and detectors is a monumental task! But PsiQuantum’s bet is clear: in the race to build the quantum computer of the future, light may prove the ultimate conductor.

🔗Read more: Nature's Article; Bloomberg's Article

2. Redwood Materials: Closing the Loop

It may look like the middle of nowhere, just a sea of sand and sage, but Redwood’s Tahoe-Reno campus is becoming the heart of a new industrial revolution. The company was founded in 2017 by J.B. Straubel, a self-described car and energy nerd (and genius), the former chief technology officer and co-founder of Tesla. Its mission is simple yet radical: to recycle the world’s used lithium-ion batteries and turn them back into the raw ingredients for new ones.

Straubel saw the challenge up close during his Tesla years: electric vehicles were accelerating, but the global supply of critical elements like lithium, nickel, and cobalt was finite and geopolitically fragile. Redwood’s answer is to build a closed-loop system: recover those metals from end-of-life batteries and manufacturing scrap, refine them, and feed them back into the next generation of EV and energy storage systems.

Unlike traditional recyclers, Redwood isn’t stopping at recovery. It also produces anode copper foil and cathode active materials, the essential layers that power every lithium-ion cell. This vertical integration gives Redwood an edge: it can both clean up the past and manufacture the future.

The company’s facilities in Nevada are already processing tens of thousands of tons of material, and new sites are scaling rapidly. With a $2 billion conditional loan from the U.S. Department of Energy and over $2 billion in private investment, including a $350 million round in 2025 led by Eclipse Ventures and Nvidia’s NVentures, Redwood is emerging as a linchpin in America’s clean-energy supply chain.

Redwood’s goal is to supply enough material by 2030 to power five million electric vehicles each year. This is a milestone that could redefine how the battery industry sources its metals. The company’s bet is that recycling isn’t just good for the planet, it’s good business in a world hungry for clean, local, and secure resources.

The task is daunting: recycling batteries at gigawatt-hour scale means complex chemistry, volatile commodity prices, and immense logistics. But Straubel’s vision remains steady: an ecosystem where nothing is wasted and every atom can find new purpose.

In a century defined by electrification, Redwood isn’t just recycling the Earth, it’s redefining our progress!

🔗Read more: CNBC Article; WSJ Podcast